Hi Everyone, I am having issues with my first EFI install so I was hoping I could get a little direction. I am new to this so please bare with me, I do pick up stuff fast but I will probably use a lot of incorrect terms. :)

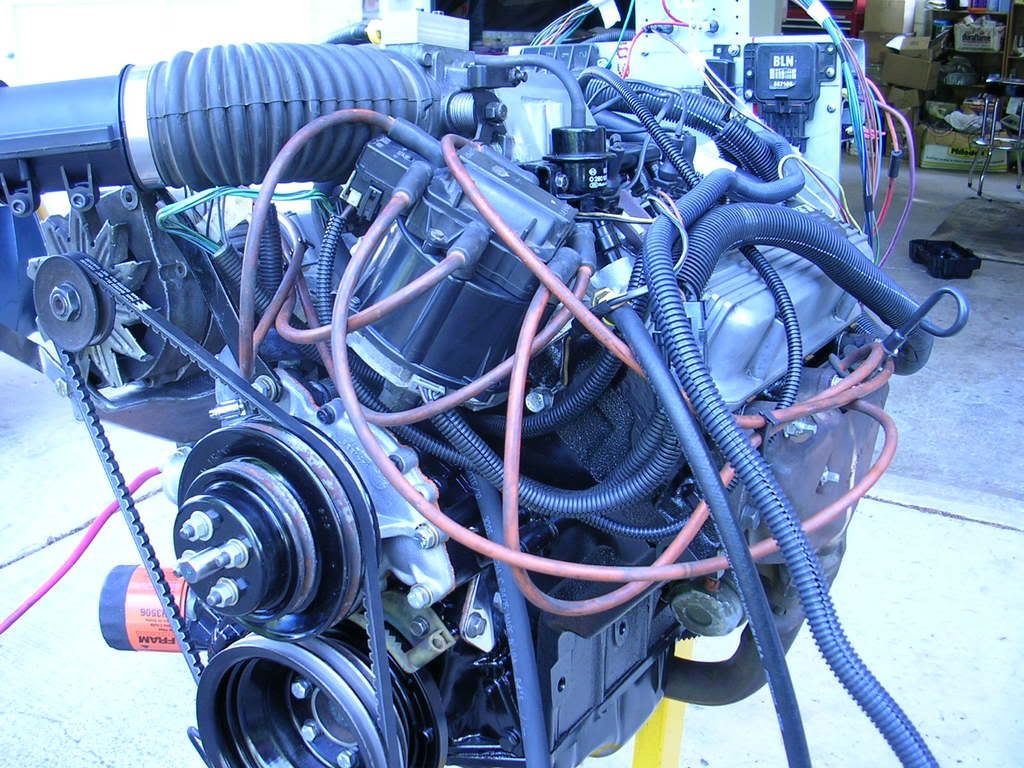

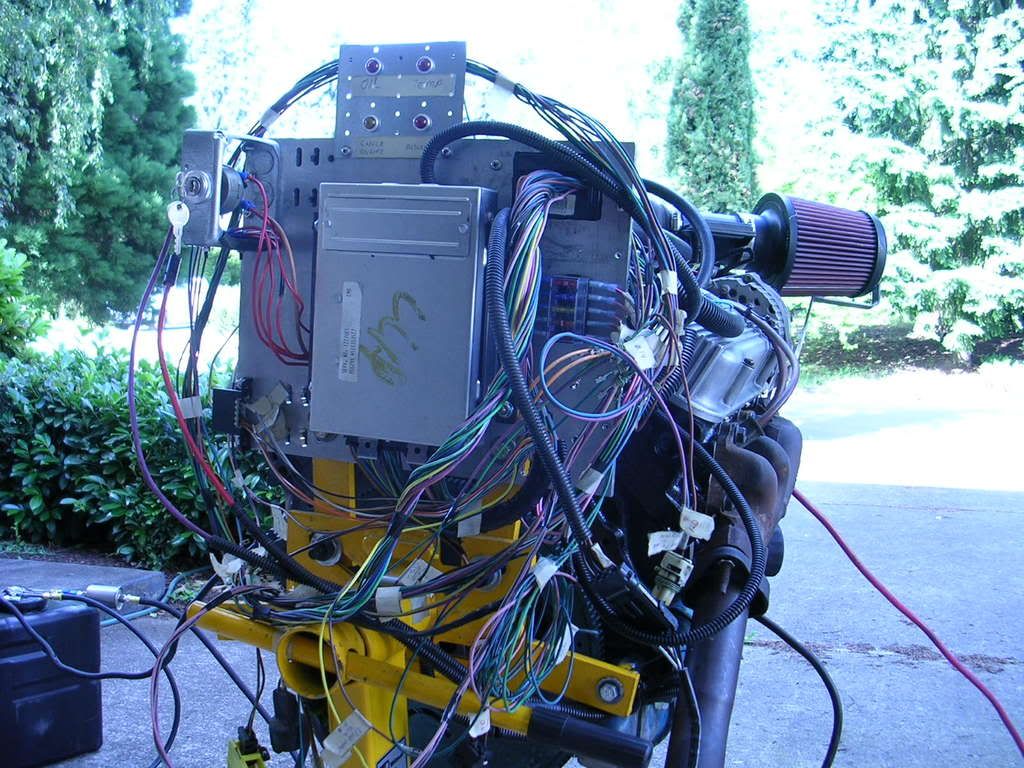

First the specs. Spent the last week installing junkyard TBI install on a 1986 Jeep Grand Wagoneer with a 360cid and auto tranny, HEI with 7pin ign module, 7747 ECM and 5.0L injectors. I was fortunate to have another member of this site help me today. FSJ Guy came by the house to help me with the tune and provided a good starting bin file. I am using TunerPro RT 5.0 with a USB autoprom. The base timing with the bypass wire disconnected was set to 12 deg.

Here are the issue we ran in to.

1. Idle pulses between 600 and 1000 rpms, tried lean and rich settings but no change

2. With bypass wire plugged in the timing is around 60deg at idle. timing shouldn't change at idle, correct?

3. Any acceleration would cause the engine to backfire and die. Timing issue, correct?

4. Engine would die shifting into drive.

My first uneducated thoughts, possibly bad IAC, incorrect 7-pin HEI module wiring and/or wrong injectors for application. Im sure FSJ Guy will also comment with his observations. Thoughts?

Thanks!

Scott R.

Reply With Quote

Reply With Quote

Bookmarks