May not be getting hot enough? If nothing else is obvious you may want to go to a heated sensor.

Bob

May not be getting hot enough? If nothing else is obvious you may want to go to a heated sensor.

Bob

Don't force it, get a bigger hammer!

Thanks Bob. I will look into converting to a heated O2 sensor.

Lee

If the 02 sensor was cooling off the engine would run rich, not lean. I would check your base timing and make sure it is set for TDC or 0*BTDC. Also check the base fuel pressure the engine is running at. These engines like to be in the 12-13 psi range even with a stock engine. Maybe as much as 14 psi with a higher flowing intake/exhaust setup. Finally check your injectors to make sure that you have the 61 lb/hr injectors, not the 46s or 55s from a 4.3 or 350. I would also suggest that dropping the coolant temp will help prevent the formation of NOx emissions. A 180*F thermostat will drop the numbers some as well.

Last edited by Fast355; 03-09-2017 at 08:48 PM.

Fast355, I will check the timing and fuel pressure. However, I have a question about the injectors. Since this is a throttle body with two injectors, how do I tell what size they are? If I remove them, will there be a number somewhere on them? I have attached two photos, one shows Rochester Products 155Z64 and the other a number 312. As you can see from the pictures, both are on the throttle body. I don't know if the injectors have separate part numbers.

Lee

If they are GM injectors the factory part number will be eteched into the top of them. Should be able to read the numbers without removing them.

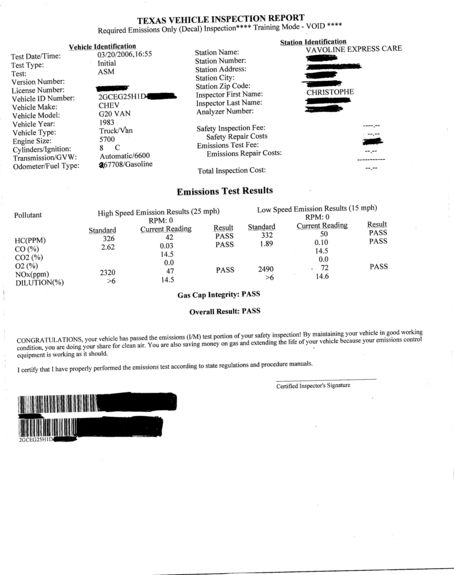

I know my old TBI in my 1983 G20 van passed with a fraction of the allowable limits. It was also not stock at the time. Had an edelbrock intake, 454 TBI unit, open center TBI spacer, 1.6:1 roller rockers, and doug thorley tri-Y headers feeding a large high flow 3" converter.

This was the last smog test it ever had to go through.

This part number is on the injector body AC 112. Next to it is another number 17064317. However, when I search AC Delco's website, it says both numbers don't exist. See

Lee

I can't follow what you are doing with the piston stop by your description and tape. The stop doesn't stop the engine at TDC so touching the stop and making a mark means nothing by itself.

You put the stop in and rotate the engine clockwise until it touches and make a mark. Then, rotate the engine counterclockwise until it touches and make another mark. TDC is in between these 2 marks.

The computer does not compensate for the timing. 2* advanced means the timing is always 2* advanced compared to the programmed timing curves.

When I learned the 1-wire O2 doesn't work in the collector of long tube headers, the engine went badly lean at idle. It would start working correctly again once the rpm's were brought up to the 1500+ rpm range.

The engine also tended to run a little lean at cruise in the 1500-2000rpm range, but that was a lack of adjusting the loop for the headers since it still occurred with a heated O2 sensor. At cruise I could hear the engine pitch slightly change every time the O2 sensor voltage went low. Some integer delay and O2 switching point adjustments were required to fix it.

The procedure you described is exactly what I did. The two silver marks in my picture were the piston stop points. The line I labeled TDC is the halfway point. The other wider black line is the one on the damper. I just guessed that the difference between those two lines is about 2 degrees. Sorry, I didn't make this clearer in my previous description. You make a good points regarding the O2 sensor and the INT adjustments. After I install the new ECM with the ASDU chip later this week, I will retest and see where things stand. If still running lean, then my next plan is to switch the single wire O2 to a 3-wire heated to perhaps compensate for the headers like you stated. If it still is running too lean, then I will probably have to make adjustments to the tables. I will need help doing that but will post the latest log file you to look at first after the above changes. Thanks for the suggestions, I really appreciate them.

Lee

2* advanced is 2* advanced over whatever has been programmed into the chip. The chip itself probably has additional advance over stock.

My experience was exactly the opposite with an unheated o2 sensor in a long tube. The o2 voltage would fall when the sensor cooled off, driving the Integrator and BLM up to their limits. It would run so rich it would actually blow black/grey smoke until the revs came up and the 02 sensor started working.

Once I receive the ECM and its stock ASDU chip and get it installed along with a new heated O2 sensor, I will set the timing to 0 degrees (with the ECM wire disconnected). Then I will run the TunerPro software and create a new log and post it here.

Lee

Hey I am providing an update. I received and installed the 1227747 ECM with the factory ASDU chip. It started right up and after a warm up period I disconnected the distributer connector and set the base timing to exactly 0 degrees TDC. Previously, it was 2 degrees advanced. Then i ran TunerPro and created another log file. There seems to be some significant improvements. First it idles at 750 or so instead of 1150, but much more importantly at part throttle is now seems to be operating much better flipping back and forth every few seconds between Lean and Rich and the O2 sensor output voltage also seems to be alternating above and below .500. Previously, part throttle seemed to stay just Lean most of the time.

I do have one question though. The vacuum and MAP numbers seem to pretty much remain constant regardless of throttle position. I don't understand this. Shouldn't the vacuum and MAP numbers drop as throttle increases?

If someone could look at the attached XDL file it would be appreciated.

Lee

Bookmarks