While I wait on my *hopefully* FTDI branded cable, I did some more work on the intake manifold.

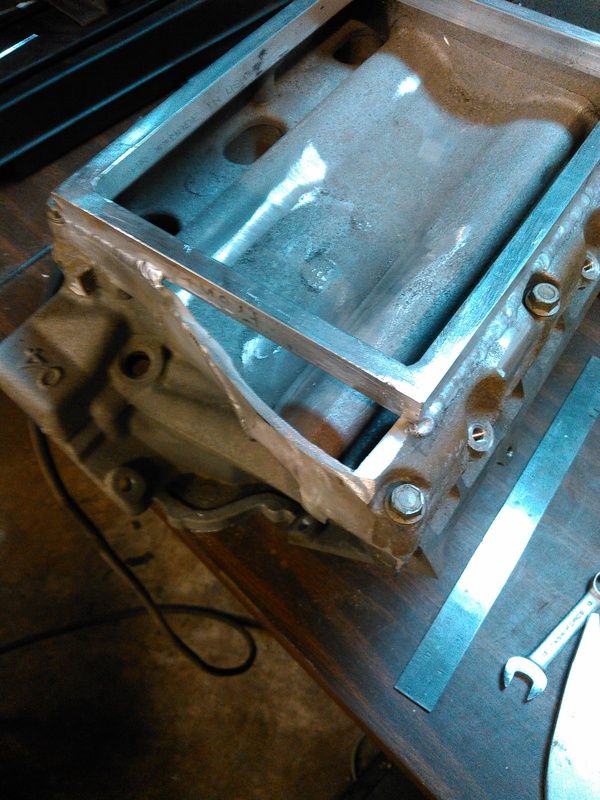

First thing to do is get it cleaned up a bit and start measuring how far off I was with the angle grinder.

It was +/- 40 thou, spent thirty minutes with a file and got it to this point:

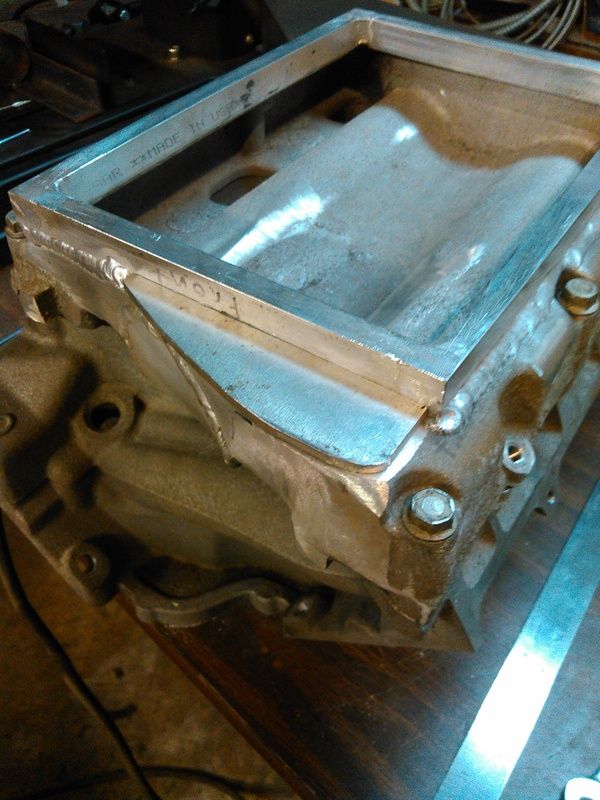

Then I welded up this frame, it's 0.750" tall and 0.500" thick bar, and it actually came out pretty square. A little clean-up on the welding and it was ready to be welded to the top of the intake casting.

Yes, I did fuck up. The sharp-eyed ones of you will notice that the intake says "front" and the frame says "back". No, it doesn't matter.

The small hole in front was easily filled in, didn't take any photos. The bigger hole in the back I did take some photos of.

I used some 0.213" thick plate that was in the big stack from page 1, it's thicker than the casting but I didn't have anymore of the 0.127" plate I used on the front. It'll be fine.

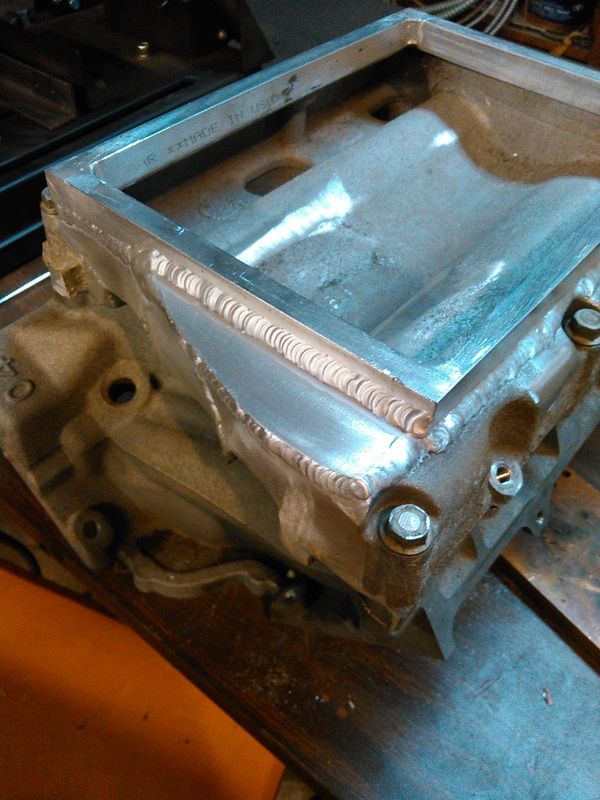

When I'm not welding on shitty castings, I can go OK with the TIG with a little rum in me. None of that white rum shit, though.

Now that the frame is welded on, I unbolted it from the lower intake manifold and measured how far it sprung during welding. The total out-of-flat was decent, pulled 0.013" total. That's totally workable, I'm gonna run it over to a buddy with a milling machine and have him skim it flat. Yeah, I *could* do it in the shop but the machined face on the bottom is slightly higher than the lowest part of the intake, so I'd have to find two slabs of plate that are parallel and flat, fit them both on the surface plate, and lap the intake against the plates...just more trouble than it's worth. Once the intake is flat and parallel then I'll start drilling and tapping the 20-something holes in the frame on top, that the supercharger plate will be bolted to. Once the plate is bolted down, I'll have to get the heads on the block and the lower intake manifold fitted, and get all the accessory drive bolted up, so I can get the supercharger drive pulley aligned and square. Once that's done and the super is fitted to the top plate, I can start on the headers.

There's no exterior differences between the 3.4L aluminum-headed hybrid I'm building, and the 2.8L iron-headed boatanchor in the truck, aside from the accessory drive. Originally, when the 3.4L engine still had iron heads on it, the exhaust manifolds were identical. I've dummied up the headers in PVC on the truck, so I'm pretty sure I won't have to clearance the truck with the BFH later when I go to bolt the new engine into place. If I have to apply the BFH, well, then I have to apply the BFH.

Reply With Quote

Reply With Quote

Bookmarks