Why, if you were already having a VE table headroom problem, would you lower the BPC?

Raising the fuel pressure, will cause a higher pressure delta, that will cause more fuel to flow for the same injector pulse width, so if you want to use fuel pressure to gain more head room in the VE table, then you would have to leave the BPC alone. All you're doing is changing the pulse width to deliver the same amount of fuel.

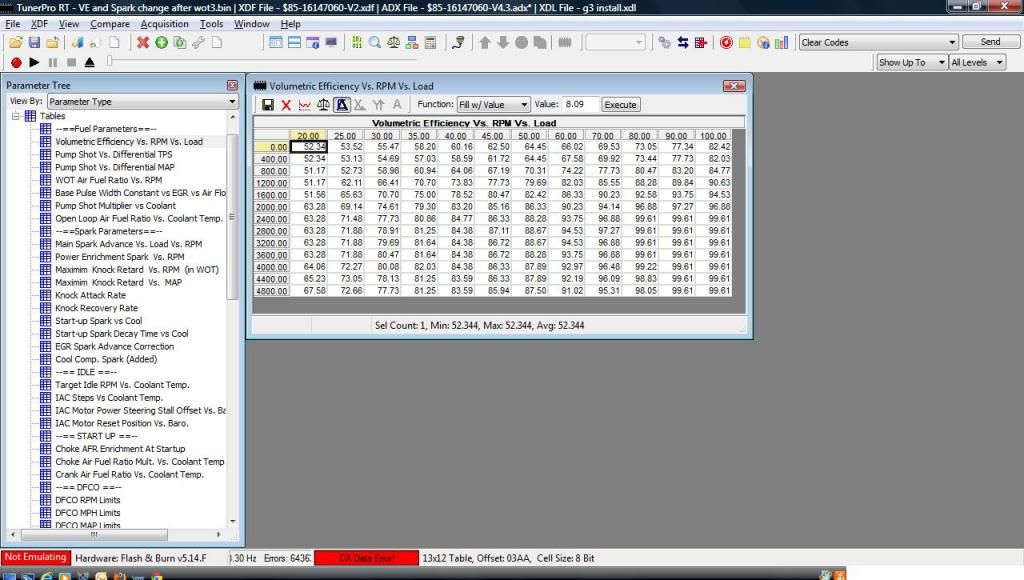

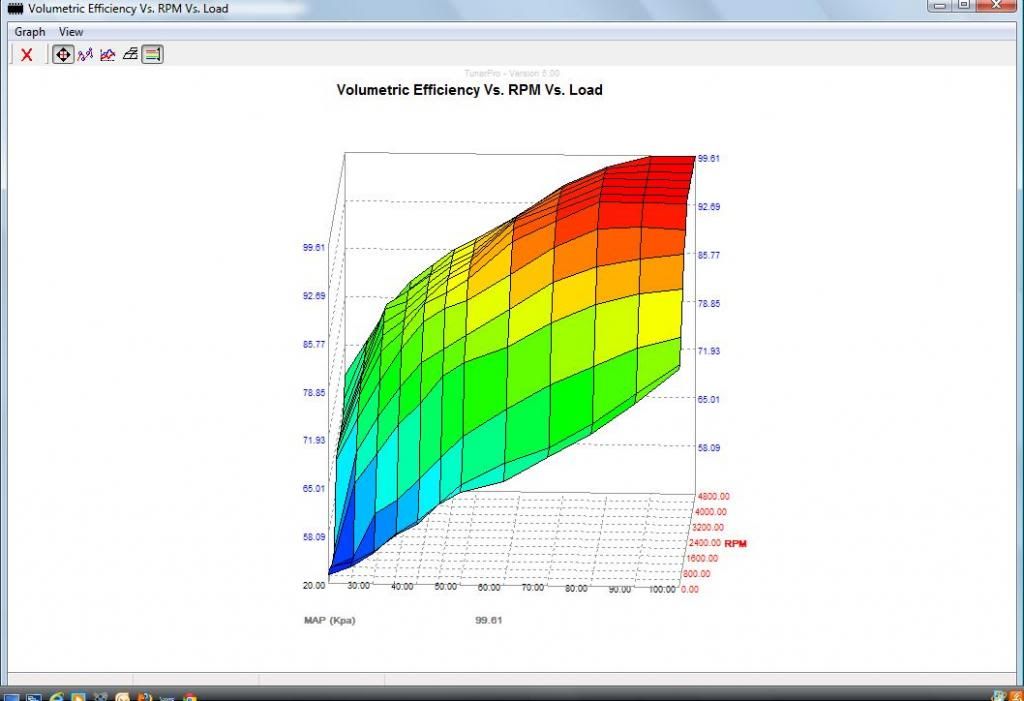

The way I prefer to do it it raise the BPC, and re-tune the VE table, to gain that head room. If you still find that you're not getting enough fuel, by maxing out the VE table (and actual duty cycle is maxing out), then you need to add more fuel pressure, larger injectors or both.

This is the EXACT reason that I do NOT use the BPC/BPW formulas that are being passed around the internet, I have NEVER found one instance where the result was anything other than non-usable.

Reply With Quote

Reply With Quote

Bookmarks