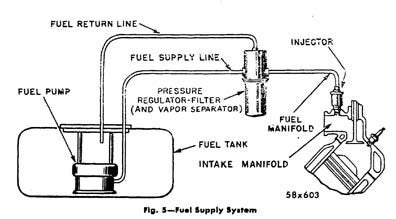

I've never seen a return line plumbed back into a fuel pump inlet. Every vehicle I've worked on, or looked at, and it's many, many vehicles, has the return line back into the tank itself, so there is little to no restriction on the return line, allowing the bypass regulator to perform it's job easily.

Reply With Quote

Reply With Quote

Bookmarks